Back to the list

Changing a wheel

Changing a wheel

Unlocking the wheel

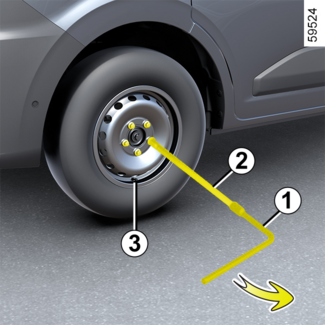

If necessary, remove the wheel trim.

Unlocking the wheel

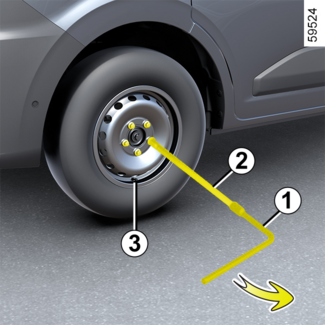

Unlock the wheel bolts using the wheel brace 1. Position it so as to be able to push from above.

Unlocking dual wheels

When removing dual wheels, unscrew inflating extension piece 3.

Do not forget to reattach it when refitting.

When removing dual wheels, unscrew inflating extension piece 1 extended using the hexagonal extension piece 2 (supplied in the tool kit) and pressing down.

Tip

Anti-theft bolt

If you use anti-theft bolts, fit these nearest the valve (wheel embellisher may not

be able to fit).

WARNING

Do not leave the tools unsecured inside the vehicle as they may be projected during

braking. After use, check that all the tools are correctly clipped into the tool kit,

then position it correctly in its housing to reduce any risk of injury.

If bolts are supplied with the emergency spare wheel, you must use these bolts only

for the emergency spare wheel.

Hydraulic jack

WARNING

If the vehicle is parked on the hard shoulder, you must warn other road users of your

vehicle's presence with a warning triangle or with other devices as per the legislation

applying to the country you are in.

WARNING

Switch on the hazard warning lights.

Keep the vehicle away from traffic and on a level surface where it will not slip.

Apply the parking brake and engage a gear (first or reverse, or in position D, M or R for automatic transmissions).

Ask the passengers to leave the vehicle and to keep away from traffic.

WARNING

For your safety, the use of a jack not recommended by the manufacturer is strictly

prohibited.

The jack is specific to the vehicle and used to change the wheels.

Under no circumstances should it be used:

- on another vehicle;

- to carry out a repair;

- to access the underside of the vehicle.

Risk of injury.

Risk of damage to the vehicle.

Using the hydraulic jack

WARNING

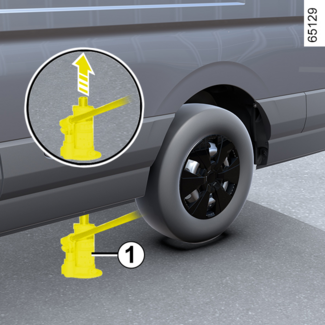

To prevent any risk of injury or damage to the vehicle, only crank the jack until

the wheel you are replacing is a maximum of 3 centimetres off the ground.

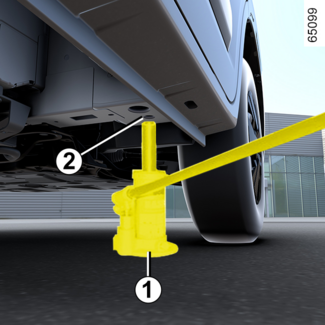

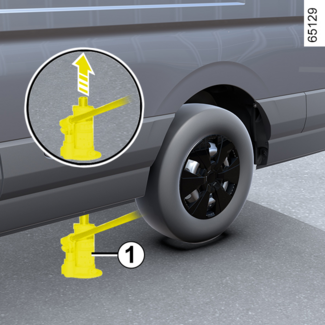

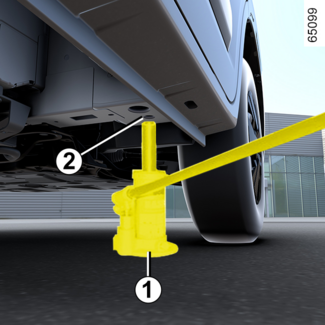

Remove the jack 1 located in the tool kit. Familiarise yourself with the jack arrangement prior to

using it.

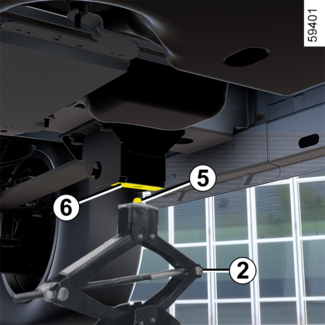

Front jack support point 2

Position the head of the jack against the contact point 2 close to the wheel concerned.

Position the jack 1 horizontally. The head of the jack must line up with the point 2 provided.

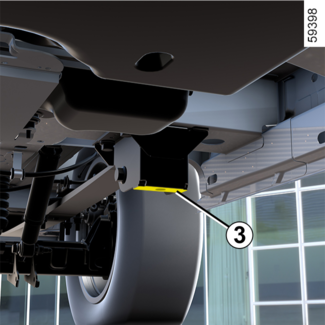

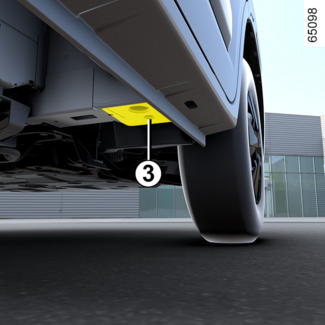

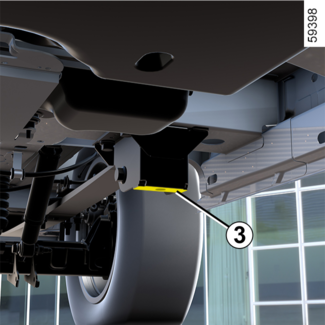

Rear jack support point 3 (van versions over 3.5 tonnes)

Position the head of the jack against the contact point 3 close to the wheel concerned.

Position the jack 1 horizontally. The head of the jack must line up with the point 3 provided.

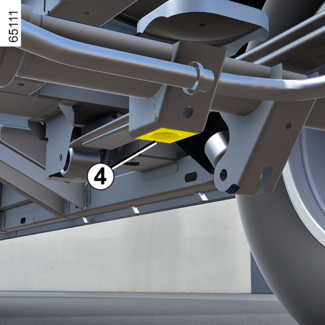

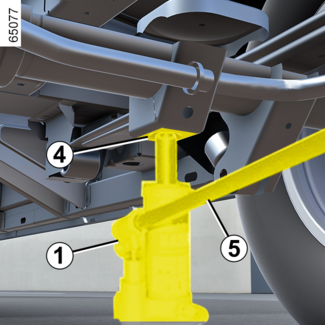

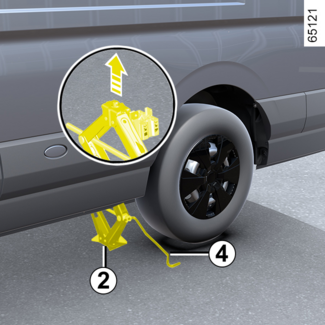

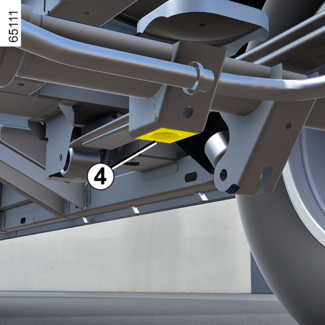

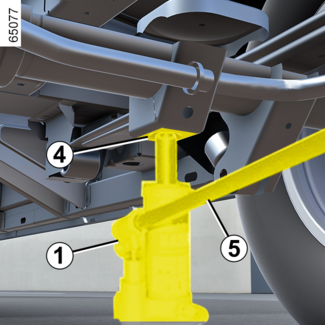

Rear jack support point 4(rear-wheel drive and chassis cab versions)

This support point must be used when changing the rear wheels for rear-wheel drive

and chassis cab vehicles.

Position the head of the jack against the contact point 4 close to the wheel concerned.

Position the jack 1 horizontally. The head of the jack must line up with the point 4 provided.

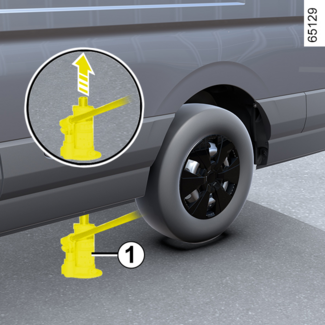

Start pumping by moving the three extension pieces 5 placed end to end, available in the tool kitTOOLS.

Free the wheel from the ground.

Note: using the three extension pieces 5 avoids having to go underneath the vehicle to use the jack 1 when raising the vehicle.

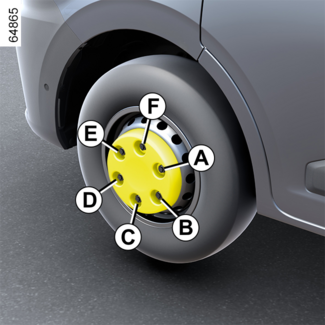

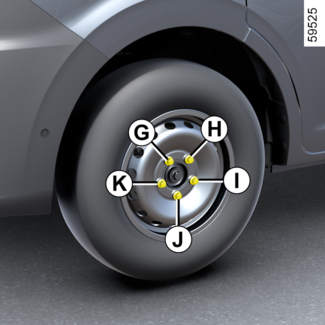

Remove the screws, then remove the wheel (take off the central wheel trim if necessary).

Fit the emergency spare wheel on the central hub and, depending on the vehicle, turn

it to align the mounting holes in the wheel and the hub.

If bolts are supplied with the emergency spare wheel, only use these bolts for the

emergency spare wheel.

Note: do not lubricate the wheel bolts

WARNING

To prevent any risk of injury or damage to the vehicle, only crank the jack until

the wheel you are replacing is a maximum of 3 centimetres off the ground.

Tighten the nuts and lower the jack.

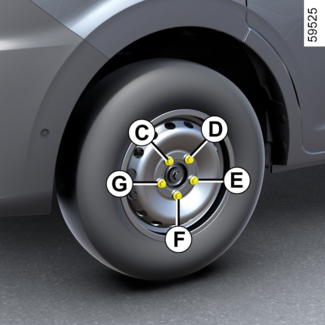

With the wheel on the ground, tighten the bolts completely, following the order of

tightening below:

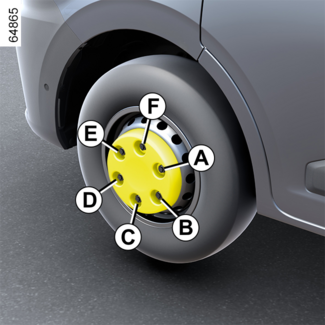

Wheel with 6 holes: start with bolt A, then D, B, E, C and end with F.

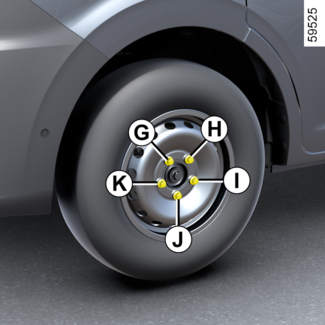

Wheel with five holes: start with bolt G, then J, H, K, and end with I.

Have the tightening and the pressure of the spare wheel checked as soon as possible.

Jack

WARNING

If the vehicle is parked on the hard shoulder, you must warn other road users of your

vehicle's presence with a warning triangle or with other devices as per the legislation

applying to the country you are in.

WARNING

Switch on the hazard warning lights.

Keep the vehicle away from traffic and on a level surface where it will not slip.

Apply the parking brake and engage a gear (first or reverse, or in position D, M or R for automatic transmissions).

Ask the passengers to leave the vehicle and to keep away from traffic.

WARNING

For your safety, the use of a jack not recommended by the manufacturer is strictly

prohibited.

The jack is specific to the vehicle and used to change the wheels.

Under no circumstances should it be used:

- on another vehicle;

- to carry out a repair;

- to access the underside of the vehicle.

Risk of injury.

Risk of damage to the vehicle.

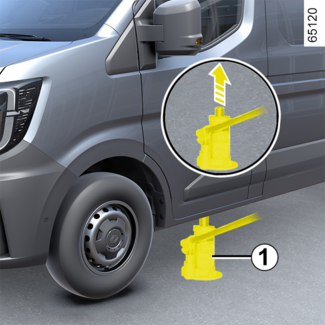

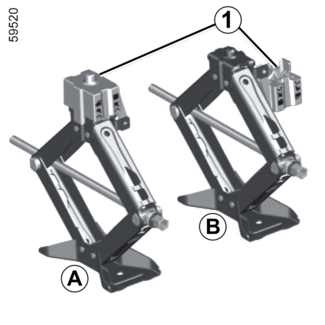

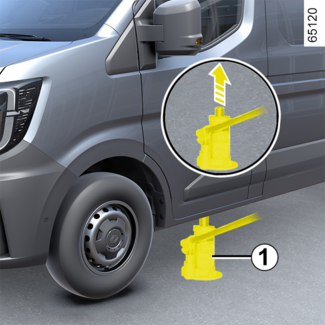

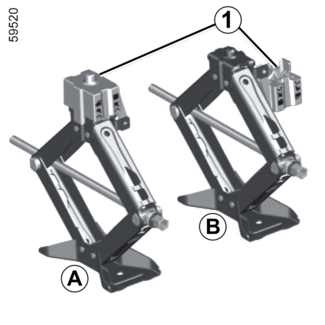

Vehicle equipped with a jack with a heightener

When changing a front wheel, use the heightener 1 (figure A).

When changing a rear wheel, remove the heightener 1 (figure B).

Using the jack

WARNING

To prevent any risk of injury or damage to the vehicle, only crank the jack until

the wheel you are replacing is a maximum of 3 centimetres off the ground.

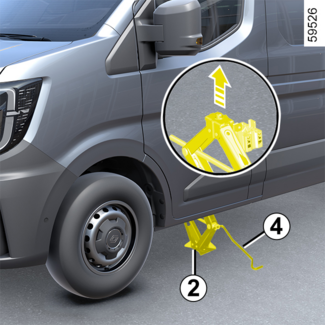

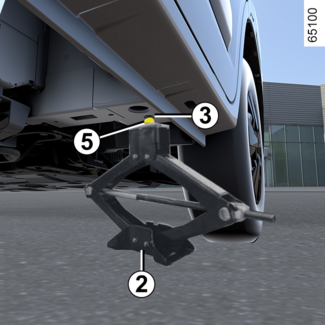

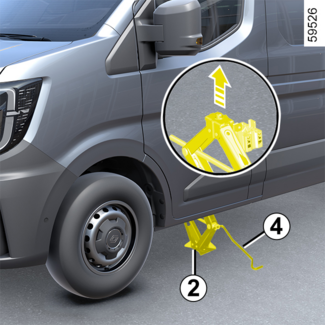

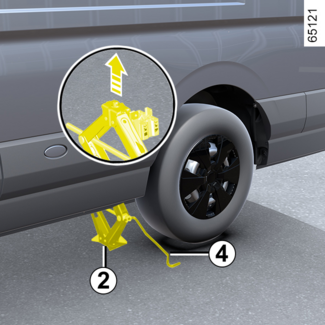

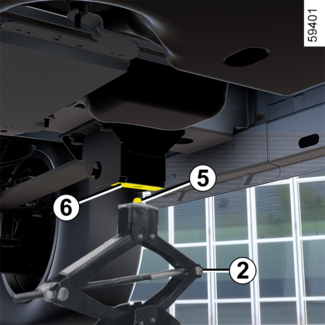

Remove the jack 2 located in the tool kit. Familiarise yourself with the jack arrangement prior to

using it.

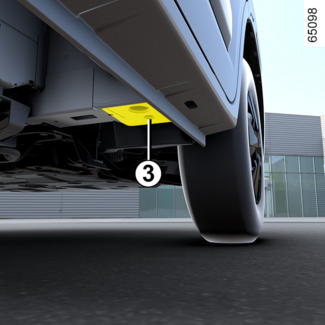

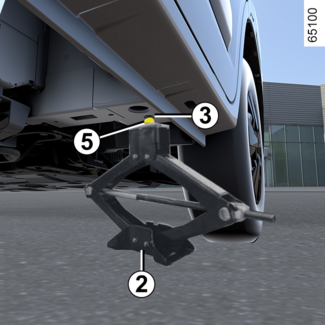

Front jack support point 3

Position the jack 2 horizontally. The head of the jack must line up with the point 3 provided.

Place the jack 2 horizontally. The jack head 5must be positioned at the same level as the support point3.

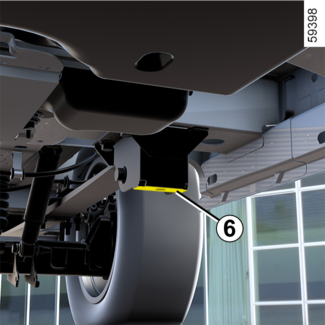

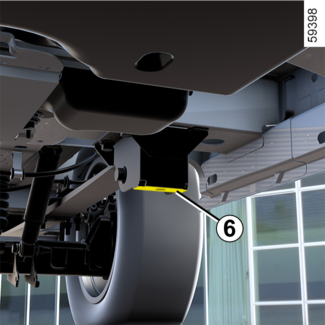

Rear jack support point 6

Position the jack 2 horizontally. The head of the jack must line up with the point 6 provided.

Place the jack 2 horizontally. The jack head 5must be positioned at the same level as the support points6.

Start cranking the jack up by hand to align the base plate (which should be pushed

slightly under the vehicle).

Turn the handle 4 a few times until the wheel comes off the ground, then remove the bolts and the wheel

itself.

Fit the emergency spare wheel on the central hub and turn it to locate the mounting

holes in the wheel and the hub.

If bolts are supplied with the emergency spare wheel, only use these bolts for the

emergency spare wheel. Tighten the bolts, checking that the wheel is correctly positioned

on its hub and unscrew the jack.

Note: do not lubricate the wheel bolts

Tip

Anti-theft bolt

If you use anti-theft bolts, fit these nearest the valve (wheel embellisher may not

be able to fit).

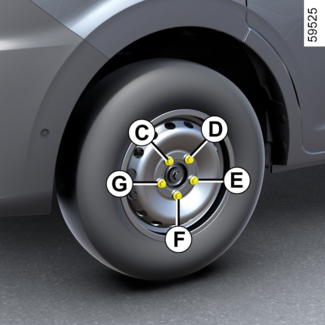

With the wheel on the ground, tighten the bolts with force, starting with side C, then E, G, D and end with F. Check the tightness and tyre pressure on the emergency spare wheel as soon as possible.

WARNING

If you have a puncture, replace the wheel as soon as possible.

A tyre which has been punctured should always be inspected (and repaired, where possible)

by a specialist.